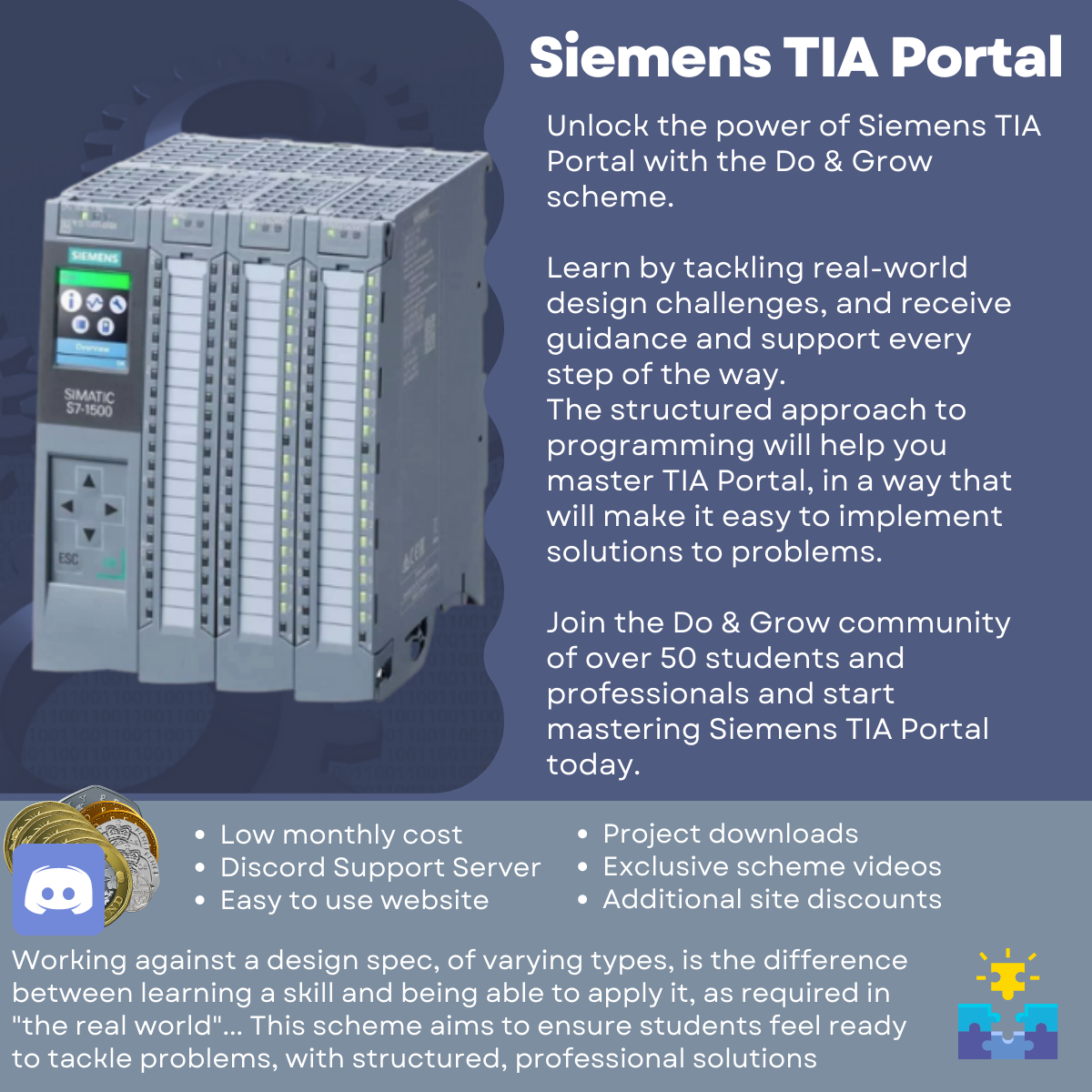

Join a growing group of students who want to learn how to tackle real world scenarios

How Long Will This Content Take Me To Complete?

As of January 2024, there’s a huge 13.5 Hours of consumable content in this membership. That’s content for you to watch and digest, you’ll need additional time for the “Do” aspect, where you explore implementing your learning into your own projects.

As a rough guide, you should double the time for any lessons and add that on for the “Do it yourself” aspect, which brings this membership up to ~40 Hours worth of time required to complete.

How much you want to implement, build, modify and enhance what you learn is endless and up to you, you could make the content in this membership stretch much farther if you choose to.

How It Works…

Built in a “Course-like” environment, scenarios, tips and solutions are posted as individual “Lessons” in the course.

Sometimes this contains documentation to work against, sometimes it contains an entire project that needs to be adapted, modified or re-worked based on some condition

The aim of the scheme is to get people “World-Ready” with Siemens TIA Portal.

Key skills are learnt such as:

🔹TIA Portal Basics – By Example🔹

🔹Reading Documentation🔹

🔹Planning & Writing Code To Specification🔹

🔹Multi-Language PLC Code🔹

🔹Fault Finding & Application Of Design Practices🔹

During the active scenario, tips and pointers are posted into the course to help tackle key areas and keep people progressing.

At the end of every scenario, a solution post is added detailing a solution to the control scenario. This is usually in the form of a video that goes into deep detail on why and how the solution was formed

Do & Grow has had over 175 members pass through, all learning and developing together. We have a dedicated Discord channel you’ll be able to access on sign up too!

🔗How Do I Join?

You aren’t enrolled, yet!

…Pick your plan…

Do & Grow – Monthly Access

Access the Do & Grow course content

+ Additional discounts and content across the site

Do & Grow – Yearly Access

Access the Do & Grow course content

+ Additional discounts and content across the site

Save with a yearly subscription

Do & Grow – One Time Payment

Access the Do & Grow course content

+ Additional discounts and content across the site

One time payment for access to all D&G benefits, old and new

FAQ

| Can I Access Previous Scenarios Once I Join? | ✅ – Yes You can access previous content from the second you sign up to the membership |

| Can I Receive Support For Previous Scenarios That Have Been Completed? | ✅ – Yes By using the Discord platform, you can ask questions in a dedicated channel, such as #feb-2023-vsd-pumping-station. Your question will be answered here, ensuring relative questions for that scenario are kept together |

| Do I Receive Solution Projects? | ✅ – Yes Projects are received in TIA Portal V16 and can be upgraded to TIA Portal V17 / V18 |

| What Happens If I Cancel My Membership? | 🔷At the end of your billing cycle, you will lose access to the Do & Grow scheme. You will also lose access to Discord and will be removed automatically |

| Can The Price Change? | 🪙 The price will always be £5.99 a month, however the initial cost will increase as more content becomes available. You’ll pay less in the long run if you subscribe early |

What’s Been Covered So Far?

With multiple scenarios under the scheme, Do & Grow has already covered a great deal of ground. Each month covers a specific topic, but also encompasses a progressive feel to learning as we compound learnings from previous scenarios.

This approach helps anyone taking part in the scheme to learn programming techniques alongside training good habits to enhance their career.

Below, you can see the course outline, click a lesson and get started. New lessons appear at the top, so you don’t have to keep scrolling down to the bottom. It’s probably easier to navigate from within the lessons themselves, so pick a control scenario and get started!

April 2024 – Revision Control

January 2024 – MQTT Communication (~60m of Content)

September 2023 – Supervisory PLC Control Scenario (~150m of Content)

February 2023 – Variable Speed Pumping Station Control Scenario (~190m of Content)

November 2022 – State Machines – Multi-process Control Scenario (~100m of Content)

📄 November 2022 – Tip #9 – Station 1 – Wash Station

Take a look at the “Wash Station” sequence state

October 2022 – Library Upgrades & ProDiag Alarm Management Control Scenario (~75m of Content)

September 2022 – PLC Design Against Existing HMI – Level Control Scenario (~90m of Content)

July 2022 – Triple Validation Test Unit Control Scenario (~90m Content)

June 2022 – Basic Pump Control Scenario (~60m Content)

You aren’t enrolled in this course, yet!

…Pick your plan…

Do & Grow – Monthly Access

Access the Do & Grow course content

+ Additional discounts and content across the site

Do & Grow – Yearly Access

Access the Do & Grow course content

+ Additional discounts and content across the site

Save with a yearly subscription

Do & Grow – One Time Payment

Access the Do & Grow course content

+ Additional discounts and content across the site

One time payment for access to all D&G benefits, old and new